Specifications:

AWS A5.4

AWS Class E347 (-15,-16,-17)

ASME SFA 5.4

UNS W34710

Description:

WT 347-16 electrodes are usually used for welding chromium-nickel alloys of similar compositions stabilized either with niobium or titanium. Electrodes depositing titanium as a stabilizing element are not commercially available because titanium is not readily transferred across the arc in shielded metal arc welding. Although niobium is the stabilizing element usually specified in Type 347 alloys, it should be recognized that tantalum is also present. Tantalum and niobium are almost equally effective in stabilizing carbon and in providing high-temperature strength. If dilution by the base metal produces a low-ferrite or fully austenitic weld metal deposit, crack sensitivity of the weld metal may increase substantially. Some applications, especially those involving high temperature service, are adversely affected if the ferrite content is too high. Consequently, a high-ferrite content should not be specified unless tests prove it to be absolutely necessary.

Tensile Strength: 75,000 psi min.

Elongation: 30% min.

Available in multiple sizes and diameters. Available in -15, -16, -17 coating.

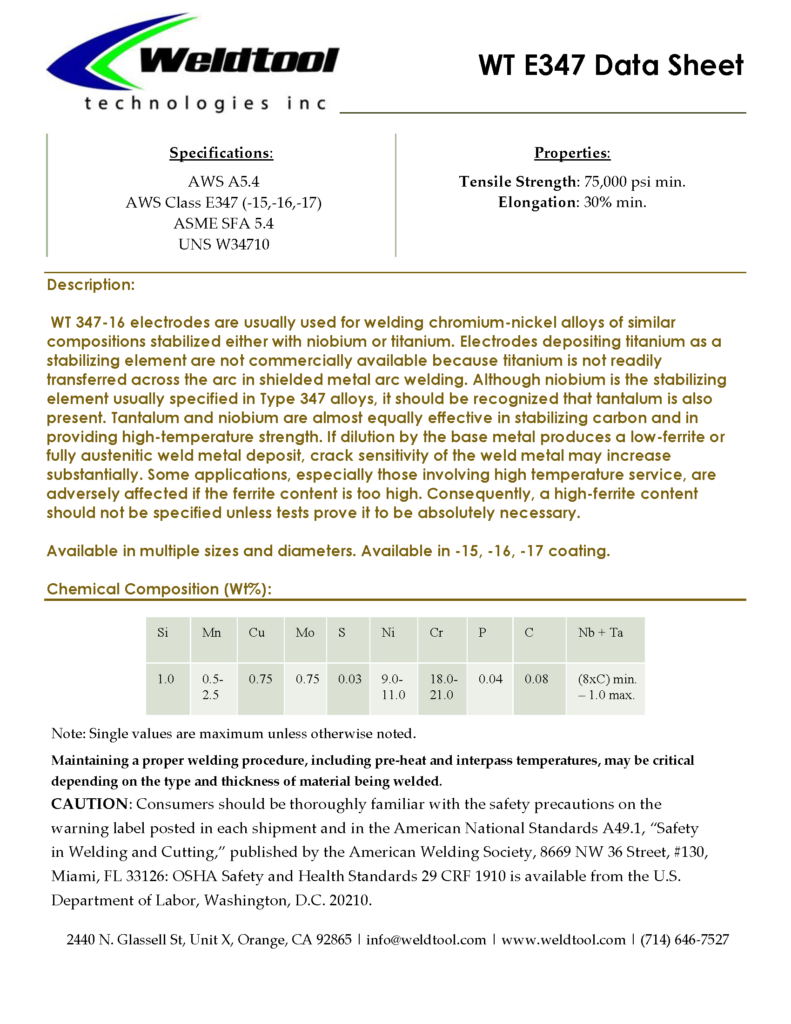

Chemical Composition (Wt%):

Note: Single values are maximum unless otherwise noted.

Si Mn Cu Mo S Ni Cr P C Nb + Ta

1.0 0.5-2.5 0.75 0.75 0.03 9.0-11.0 18.0-21.0 0.04 0.08 (8 x C) min - 1.0 max