Specifications:

AISI P-20

Typical Properties:

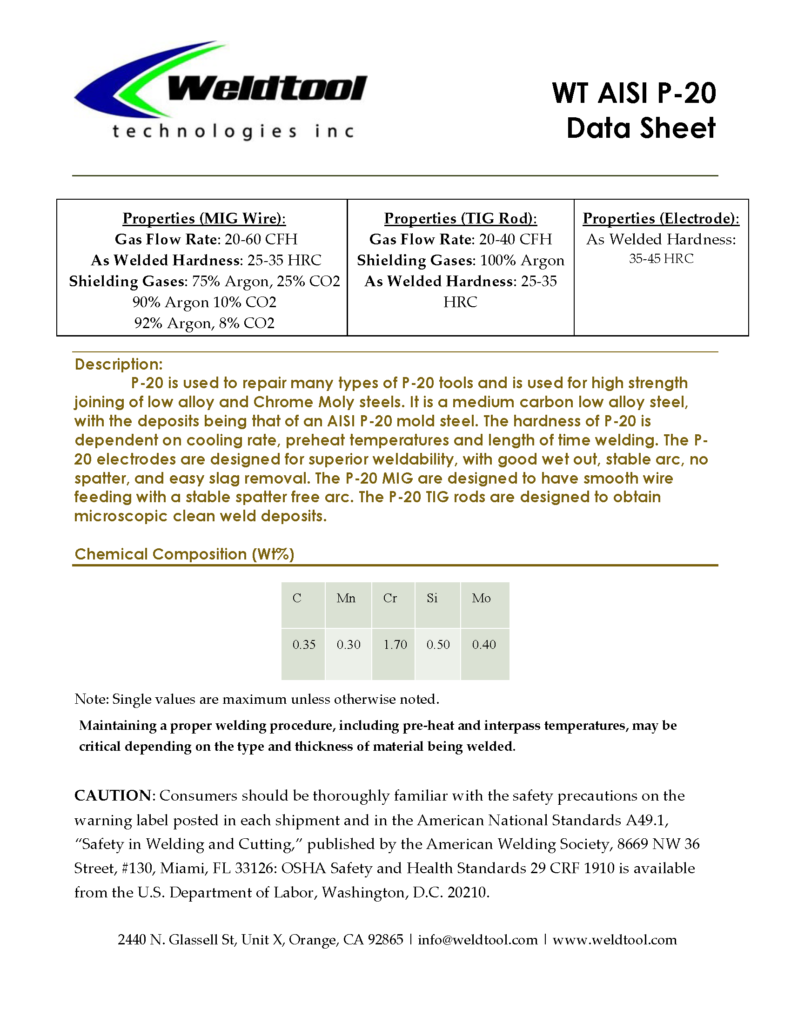

| MIG | TIG | Electrode |

| Gas Flow Rate: 20-60 CFH As Welded Hardness: 25-35 HRC Shielding Gases: 75% Argon, 25% CO2 90% Argon 10% CO2 92% Argon, 8% CO2 | Gas Flow Rate: 20-40 CFH Shielding Gases: 100% Argon As Welded Hardness: 25-35 HRC | As Welded Hardness: 35-45 HRC |

Description:

P-20 is used to repair many types of P-20 tools and is used for high strength joining of low alloy and Chrome Moly steels. It is a medium carbon low alloy steel, with the deposits being that of an AISI P-20 mold steel. The hardness of P-20 is dependent on cooling rate, preheat temperatures and length of time welding. The P-20 electrodes are designed for superior weldability, with good wet out, stable arc, no spatter, and easy slag removal. The P-20 MIG are designed to have smooth wire feeding with a stable spatter free arc. The P-20 TIG rods are designed to obtain microscopic clean weld deposits.

Chemical Composition (Wt%):

Note: Single values are maximum unless otherwise noted.

C Mn Cr Si Mo

0.35 0.30 1.70 0.50 0.40