Specifications:

AISI H13

EN10204 3.1 2.2

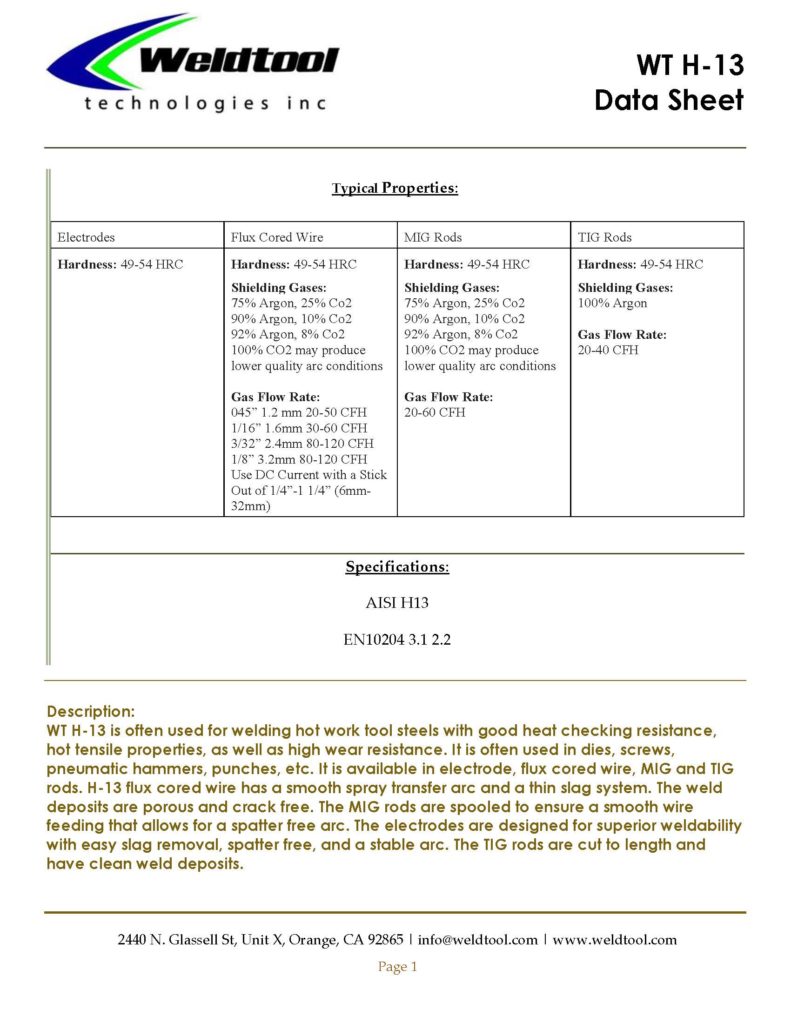

Typical Properties:

| Electrodes | Flux Cored Wire | MIG Rods | TIG Rods |

| Hardness: 49-54 HRC | Hardness: 49-54 HRC Shielding Gases: 75% Argon, 25% Co2 90% Argon, 10% Co2 92% Argon, 8% Co2 100% CO2 may produce lower quality arc conditions Gas Flow Rate: 045” 1.2 mm 20-50 CFH 1/16” 1.6mm 30-60 CFH 3/32” 2.4mm 80-120 CFH 1/8” 3.2mm 80-120 CFH Use DC Current with a Stick Out of 1/4”-1 1/4” (6mm-32mm) | Hardness: 49-54 HRC Shielding Gases: 75% Argon, 25% Co2 90% Argon, 10% Co2 92% Argon, 8% Co2 100% CO2 may produce lower quality arc conditions Gas Flow Rate: 20-60 CFH | Hardness: 49-54 HRC Shielding Gases: 100% Argon Gas Flow Rate: 20-40 CFH |

Description:

WT H-13 is often used for welding hot work tool steels with good heat checking resistance, hot tensile properties, as well as high wear resistance. It is often used in dies, screws, pneumatic hammers, punches, etc. It is available in electrode, flux cored wire, MIG and TIG rods. H-13 flux cored wire has a smooth spray transfer arc and a thin slag system. The weld deposits are porous and crack free. The MIG rods are spooled to ensure a smooth wire feeding that allows for a spatter free arc. The electrodes are designed for superior weldability with easy slag removal, spatter free, and a stable arc. The TIG rods are cut to length and have clean weld deposits.

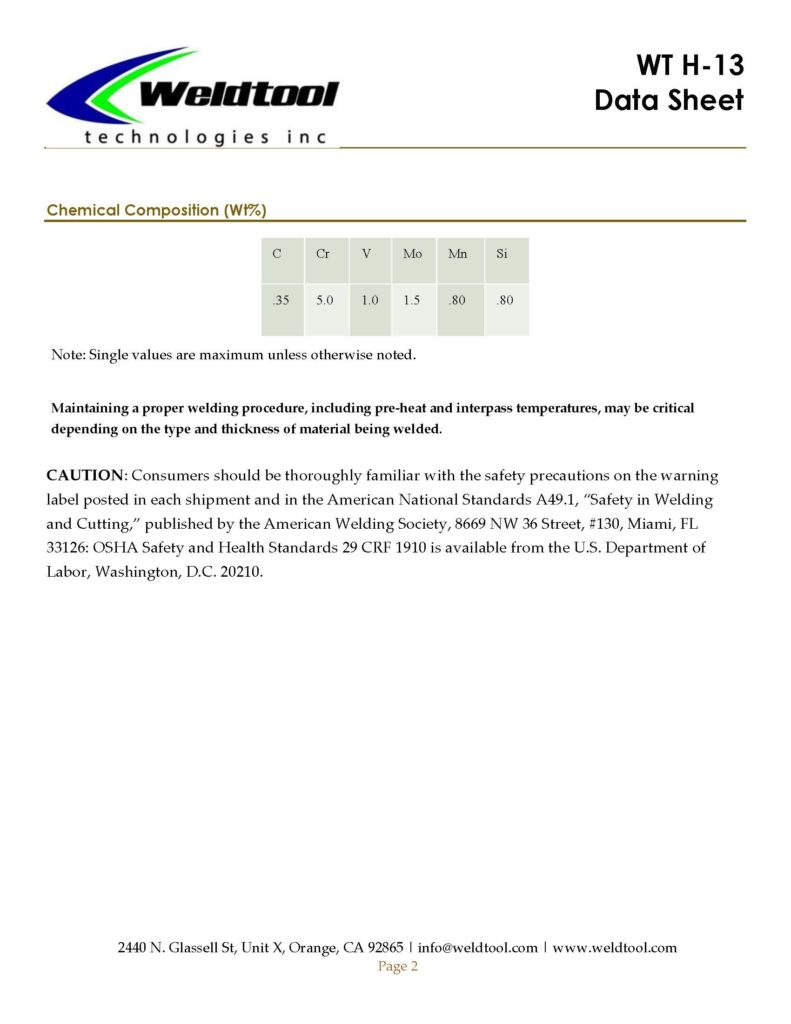

Chemical Composition (Wt%):

| C | Cr | V | Mo | Mn | Si |

| .35 | 5.0 | 1.0 | 1.5 | .80 | .80 |