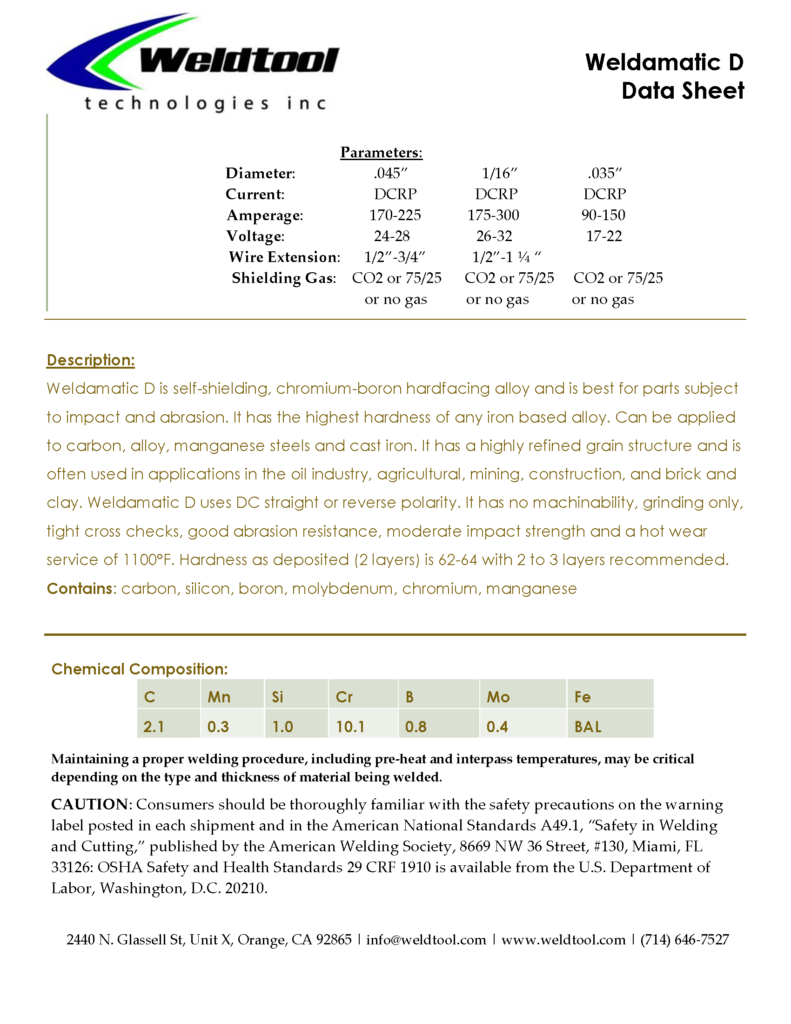

Parameters:

Diameter: .045” 1/16” .035”

Current: DCRP DCRP DCRP

Amperage: 170-225 175-300 90-150

Voltage: 24-28 26-32 17-22

Wire Extension: 1/2”-3/4” 1/2”-1 ¼”

Shielding Gas: CO2 or 75/25 CO2 or 75/25 CO2 or 75/25

or no gas or no gas or no gas

Description:

Weldamatic D is self-shielding, chromium-boron hardfacing alloy and is best for parts subject to impact and abrasion. It has the highest hardness of any iron based alloy. Can be applied to carbon, alloy, manganese steels and cast iron. It has a highly refined grain structure and is often used in applications in the oil industry, agricultural, mining, construction, and brick and clay. Weldamatic D uses DC straight or reverse polarity. It has no machinability, grinding only, tight cross checks, good abrasion resistance, moderate impact strength and a hot wear service of 1100°F. Hardness as deposited (2 layers) is 62-64 with 2 to 3 layers recommended.

Contains: carbon, silicon, boron, molybdenum, chromium, manganese

Chemical Composition:

C Mn Si Cr B Mo Fe

2.1 0.3 1.0 10.1 0.8 0.4 BAL